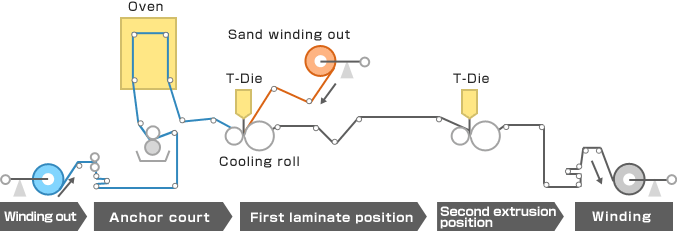

The extrusion lamination process can be repeated until the final flexible packaging structure is complete or it can be combined with adhesive lamination to create the final flexible packaging lamination.

Co extrusion lamination process.

Lamination in house lamination allows us to maintain the highest quality during this key stage of manufacturing.

Extrusion coating lamination machine lamination plant.

We are capable of water based solventless or solvent based lamination.

The added value of extrusion lamination.

The highest performing laminating inks on the market for adhesive and extrusion lamination.

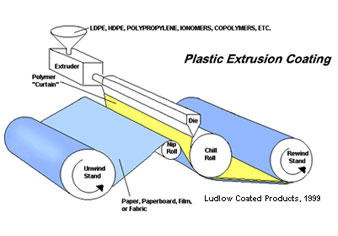

Extrusion coating is one of the processes used to produce a large range of thin multilayer structures.

Extrusion laminating is a similar process except that the extruded hot molten resin acts as the bonding medium to a second web of material.

Both processes allow us to create custom packaging films to meet specific performance criteria.

Extrusion coating and extrusion laminating are converting processes that allow different substrate materials to be combined to obtain a.

Purchase extrusion coating lamination and coextrusion 1st edition.

Specially formulated for retort boil in bag and an extraordinary range of diverse packaging applications it is a proprietary single component universal ink system that prints clean and sharp with outstanding quality and consistency on multiple.

Conversion as part of our end to end manufacturing process we can produce pre made stand up pouches wicketed bags and more.

In the expected future with the different levels of window films continuously launched in the market there is a big hope that lamination process can replace the current co extrusion process in large scale.

Another lamination process uses a lamination press after materials are combined in a thicker structure than film.

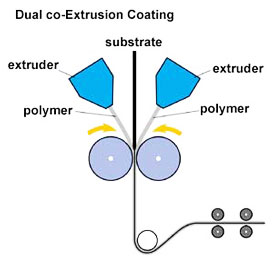

Co extrusion edit co extrusion is again a similar process but with two or more extruders coupled to a single die head in which the individually extruded melts are brought together and finally.